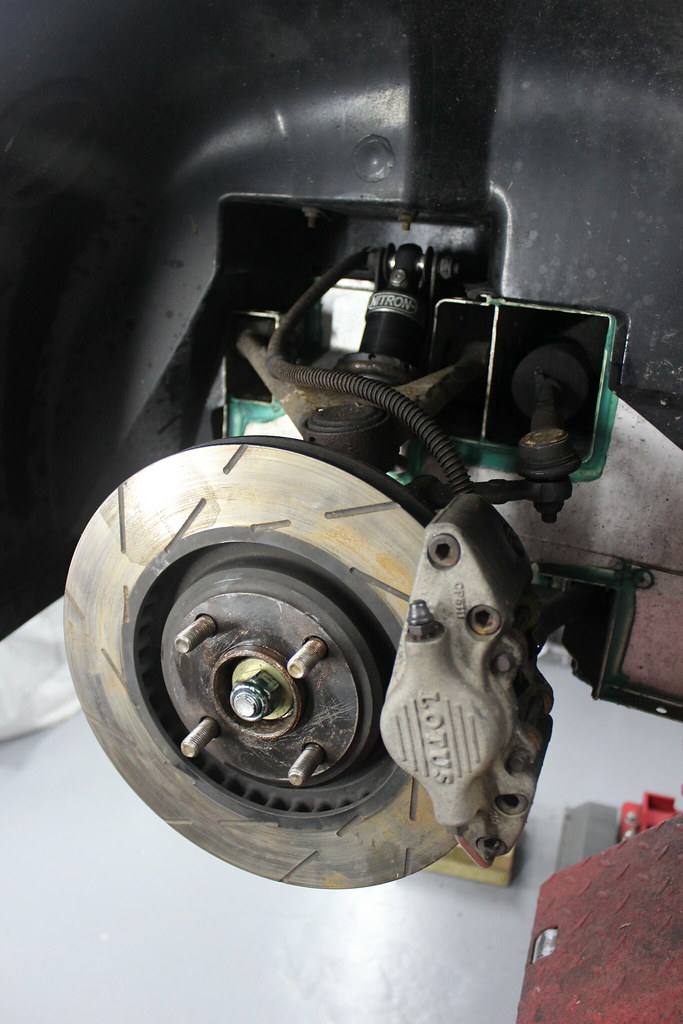

The brake caliper needs to come off first, starting with the clamp for the brake hose.

Then the two caliper bolts.

With the disc off too next was the disc shield. As expected, the bolts were not keen on coming out. After cutting a slot in the head of the bolts I used my drill on a low torque screw driver setting to start with slowly increasing the torque. This had the same action as an impact wrench and slowly worked the bolt loose without making a mess of the head.

The slotted head I cut in with a hacksaw.

Took a while but got it off in the end.

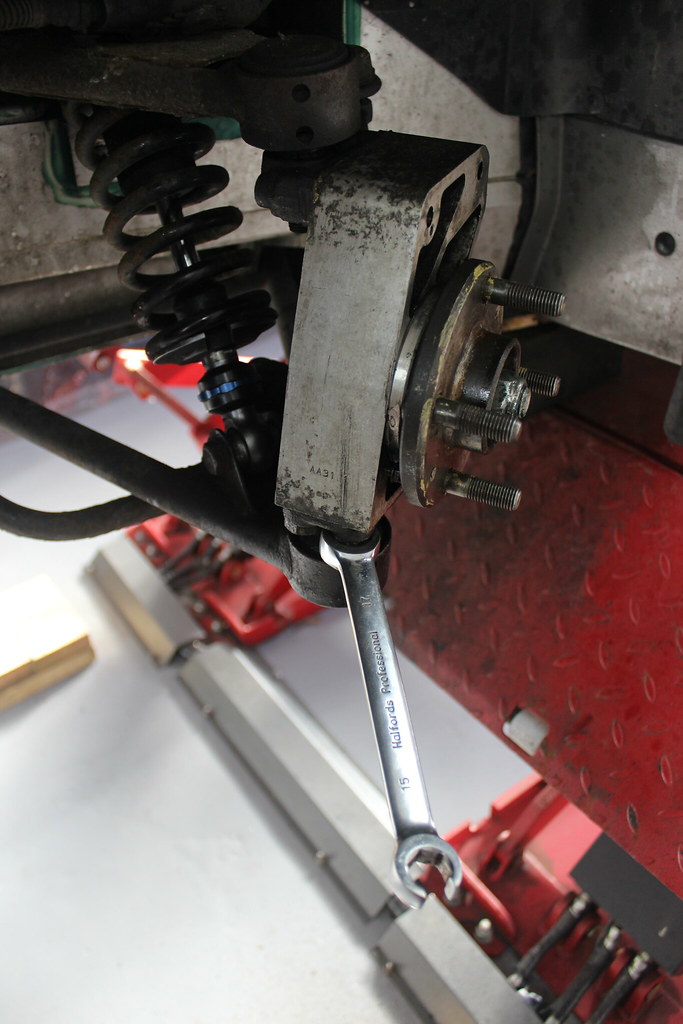

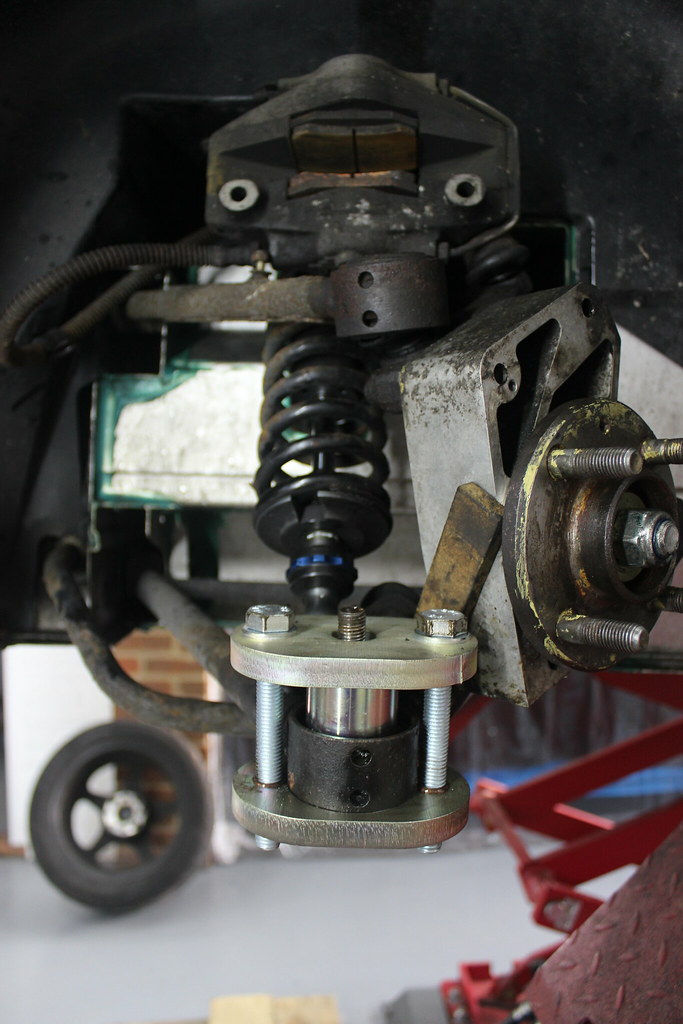

Next removing the ball joint plinth from the hub carrier/upright.

A bit of assistance to split the two.

This tool is perfect for this. No need to try holding on to the plinth while also trying to turn the nut that is now stupidly tight etc etc. This just buzzes it off with no fuss! Well worth the £140 it cost especially when it comes to doing 8 of them.

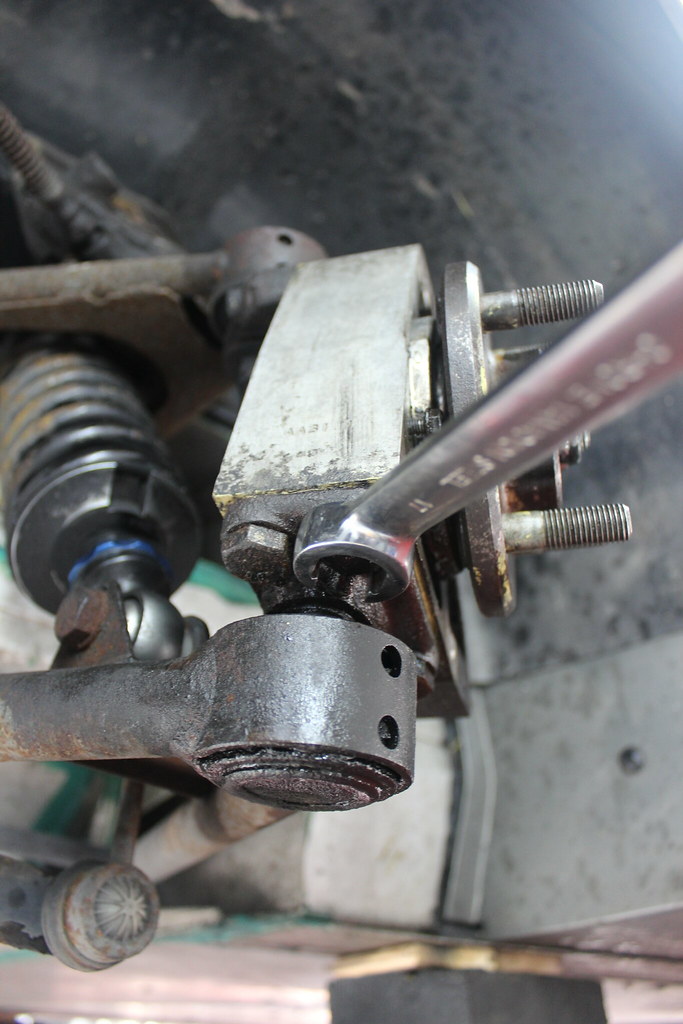

Trusty old ball joint splitter on. I always leave the nut on the joint threaded about 3/4 on as it really helps locate the splitter and stops it sliding off.

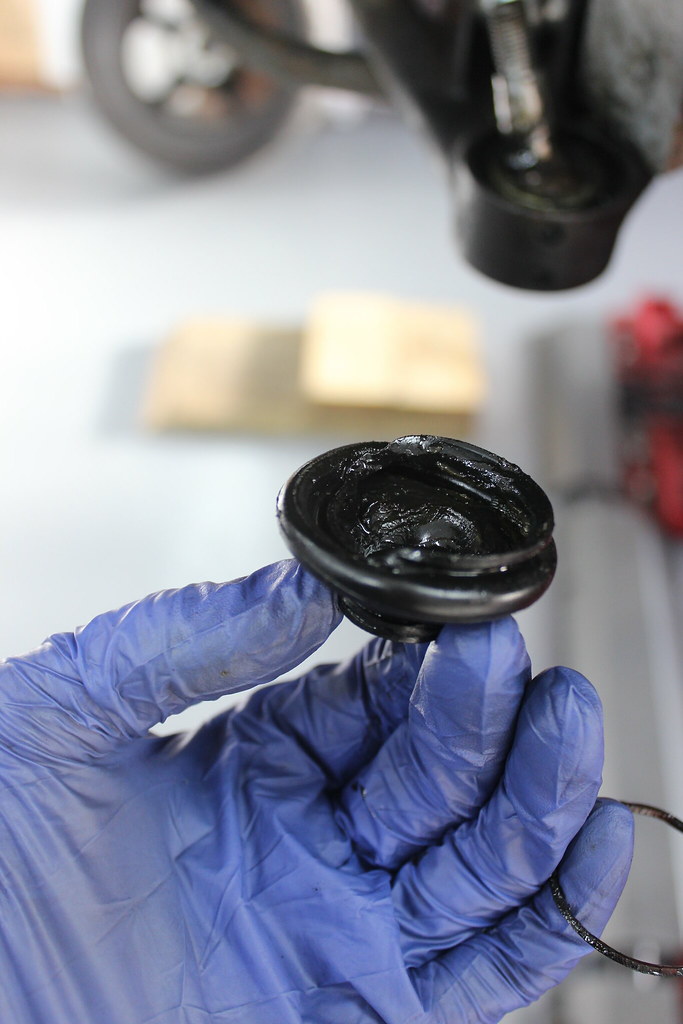

The ball joint boot was not in a great state.

It had clearly let water in, hence the rusty brown colour of the ball and it’s eventual failure.

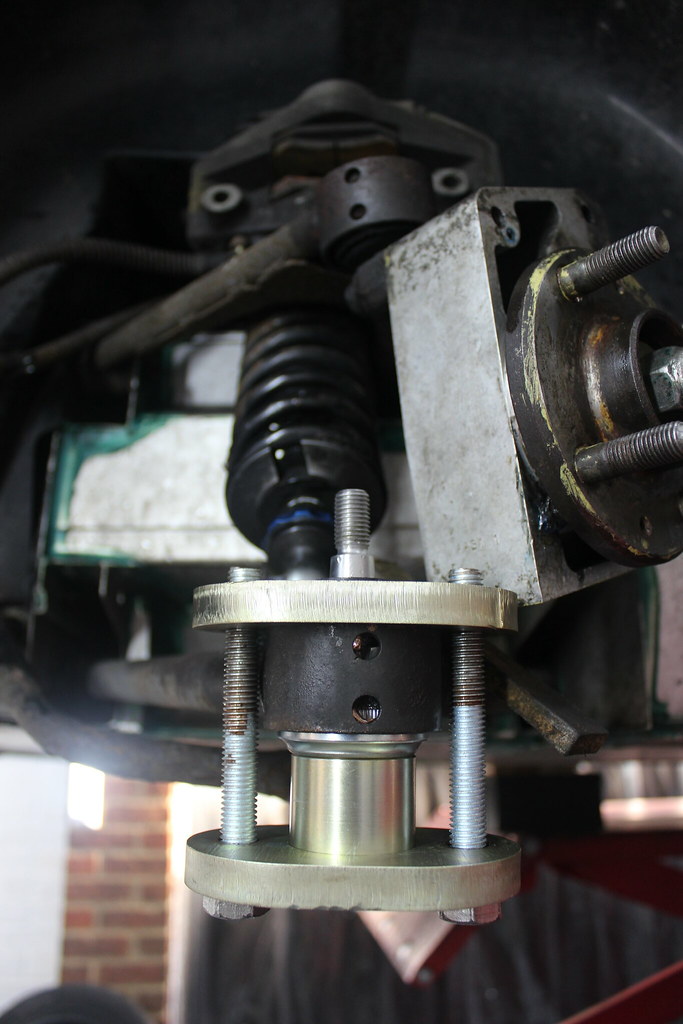

I got one of the ball joint tools from Elise Parts as having the right tool for the job is usually the best way of doing anything and it’s inexpensive. Glad I got it as it made easy work of pressing the old joint out and new one in.

Pressing out the old ball joint.

There it goes.

Cleaned up ready for the new ball joint.

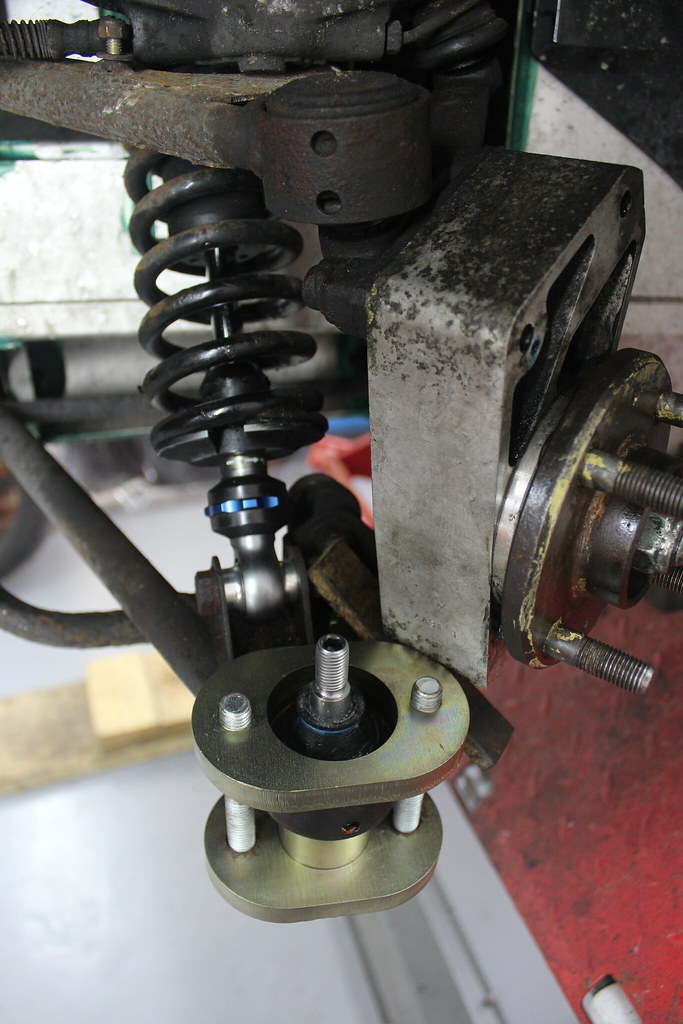

Pressing the new joint in with a little bit of copper grease on the surfaces.

Plinth and hub carrier faces cleaned up ready for reassembly.

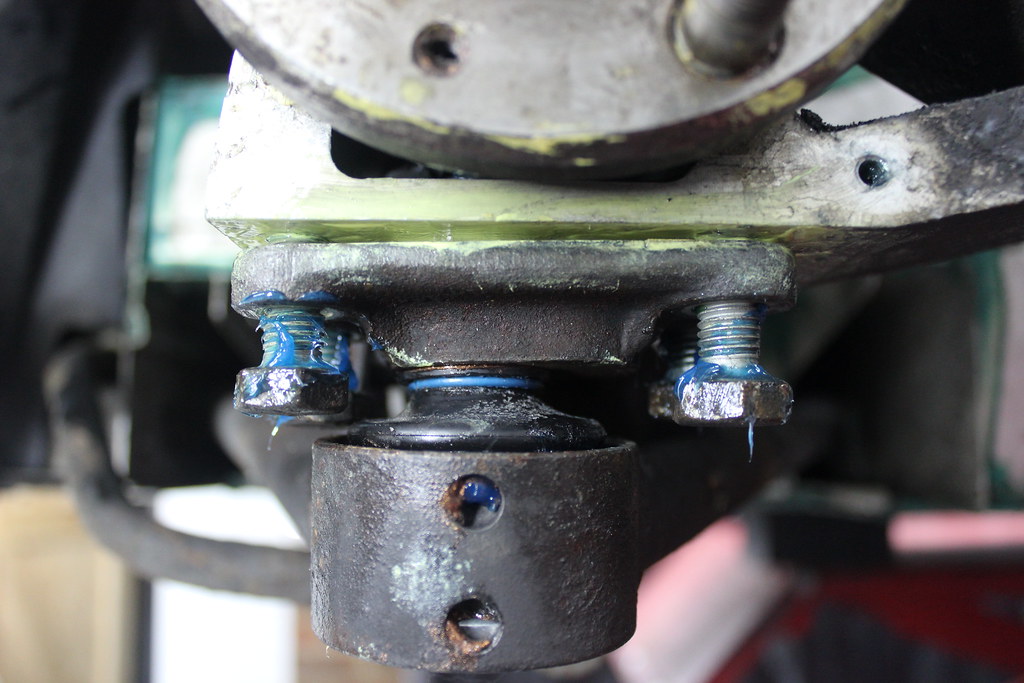

New additions to my consumables about to get some use.

Threadlock on the bolts.

Messy. I added a little corrosion block grease to the head ends of the bolts after screwing them in. This way it won’t have got on to the part of the thread that has thread lock on it but will help prevent moisture getting in.

There is a chance I used too much Duralac. 😀

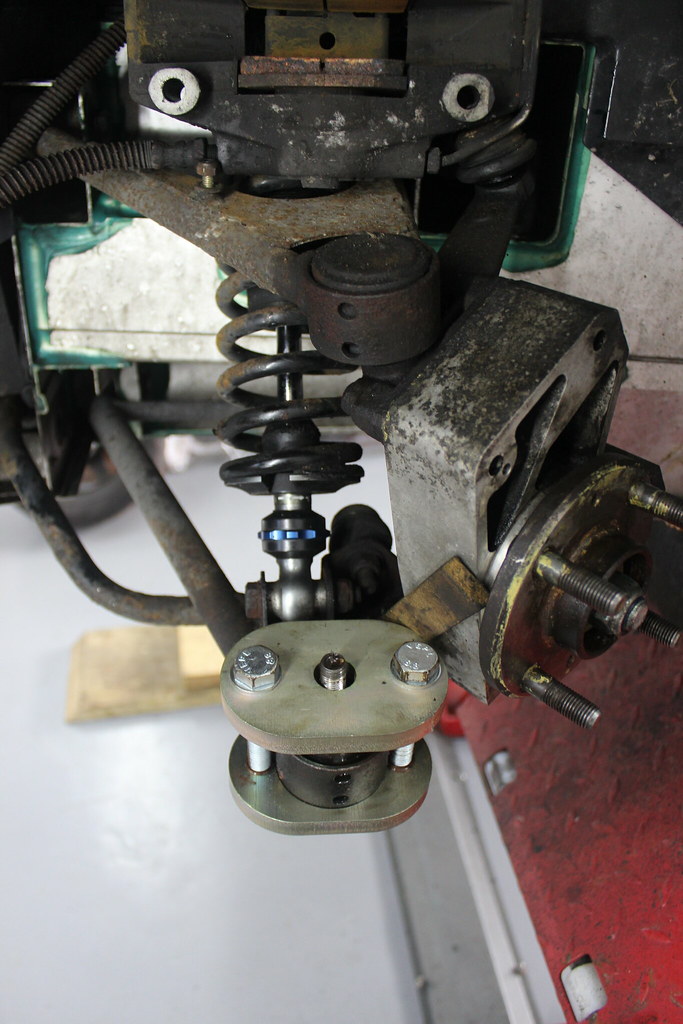

Going back together.

Done

Well that’s another little job ticked off and I’m getting to know the Elise. I quite like it’s modular design and how it goes together.

Torque values for this job:

Ball Joint Plinth to Hub Carrier Bolts – 45Nm

Ball Joint to Plinth Nut – 55Nm

Brake Caliper to Hub Carrier Bolts – 45Nm