Corrosion of the Elise/Exige/VX220/Evora chassis is a thing and it’s something that I think should not be ignored by anyone looking to buy one of these cars. Also anyone who owns one that’s done a fair bit of winter road miles or is just a good few years old now should consider inspecting their chassis carefully.

Below is a picture taken from a Pistonheads thread here, started in 2009 by an owner who got a pretty nasty surprise with the extent of corrosion on his chassis that caused a suspension pickup point to fail.

There are more pictures and information on this problem in my previous post here ‘Lotus Elise Chassis Damage and Corrosion, What to Look for’

To avoid ending up with anything like the above I looked as much as I could at the underside of my Elise before driving away in it and couldn’t see any signs of accident damage to the chassis or corrosion but that’s not the same as getting a proper look when it’s up on the lift with all the suspension removed. So now, mid suspension refresh, was the time to have a really careful inspection and take lots of pictures as a record. I won’t put them all here as I took so many but here’s a few of them.

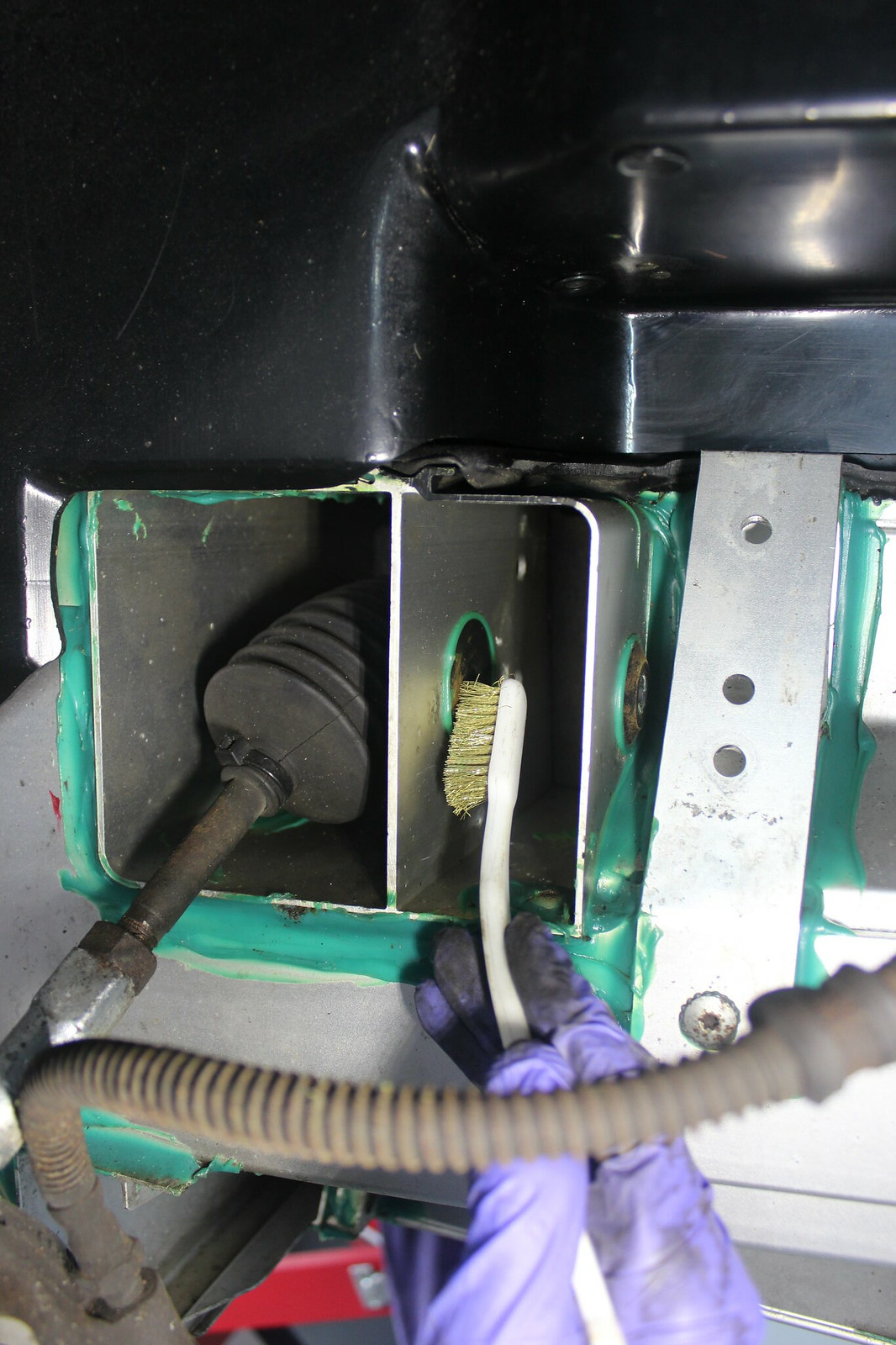

First off though, I went round all the steel inserts with a small wire brush to remove any flaking paint as they would clearly benefit from a new coating before reassembly. I was very careful not to make contact at all with the aluminium chassis as any damage of the anodising would only encourage corrosion.

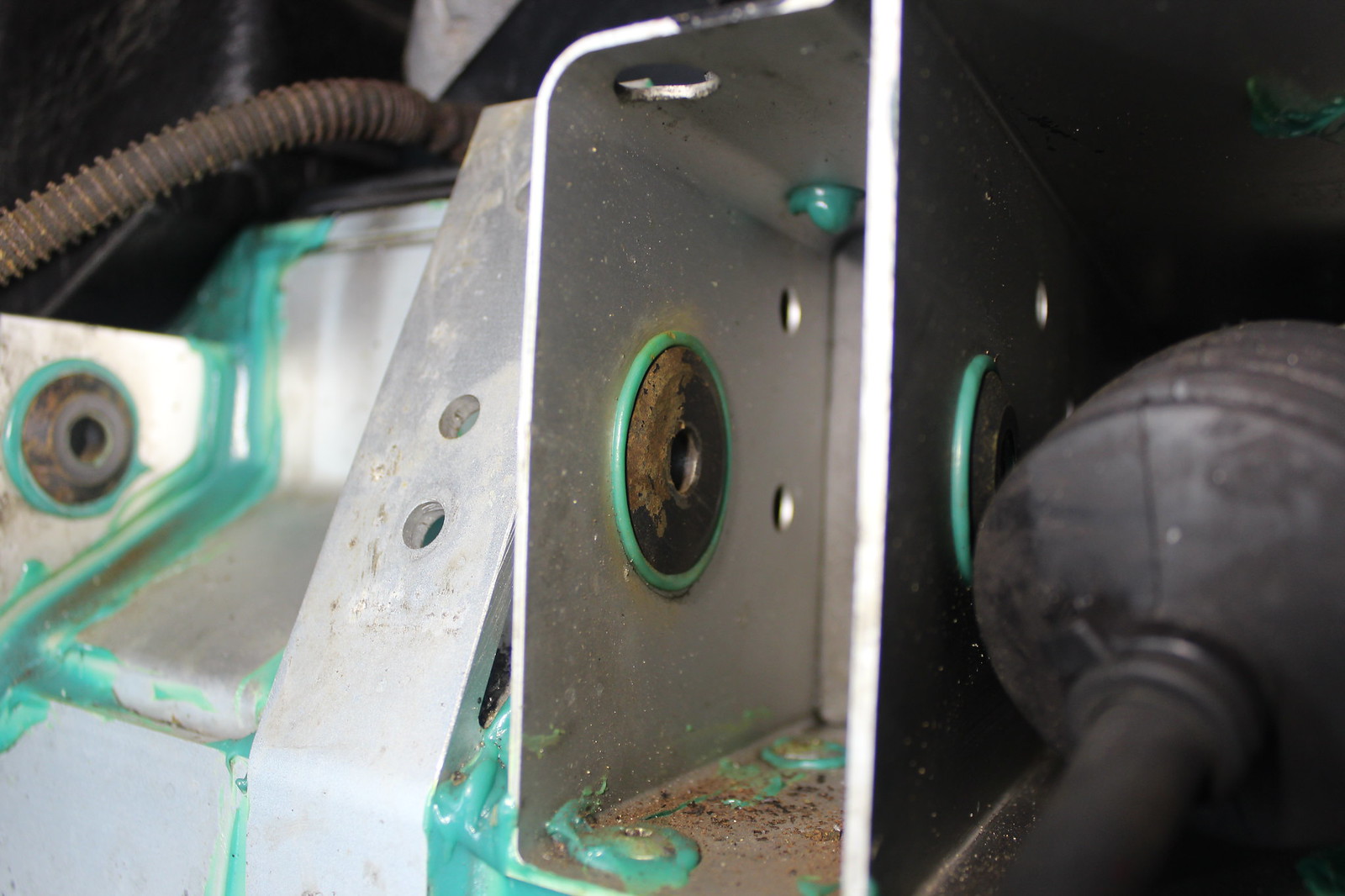

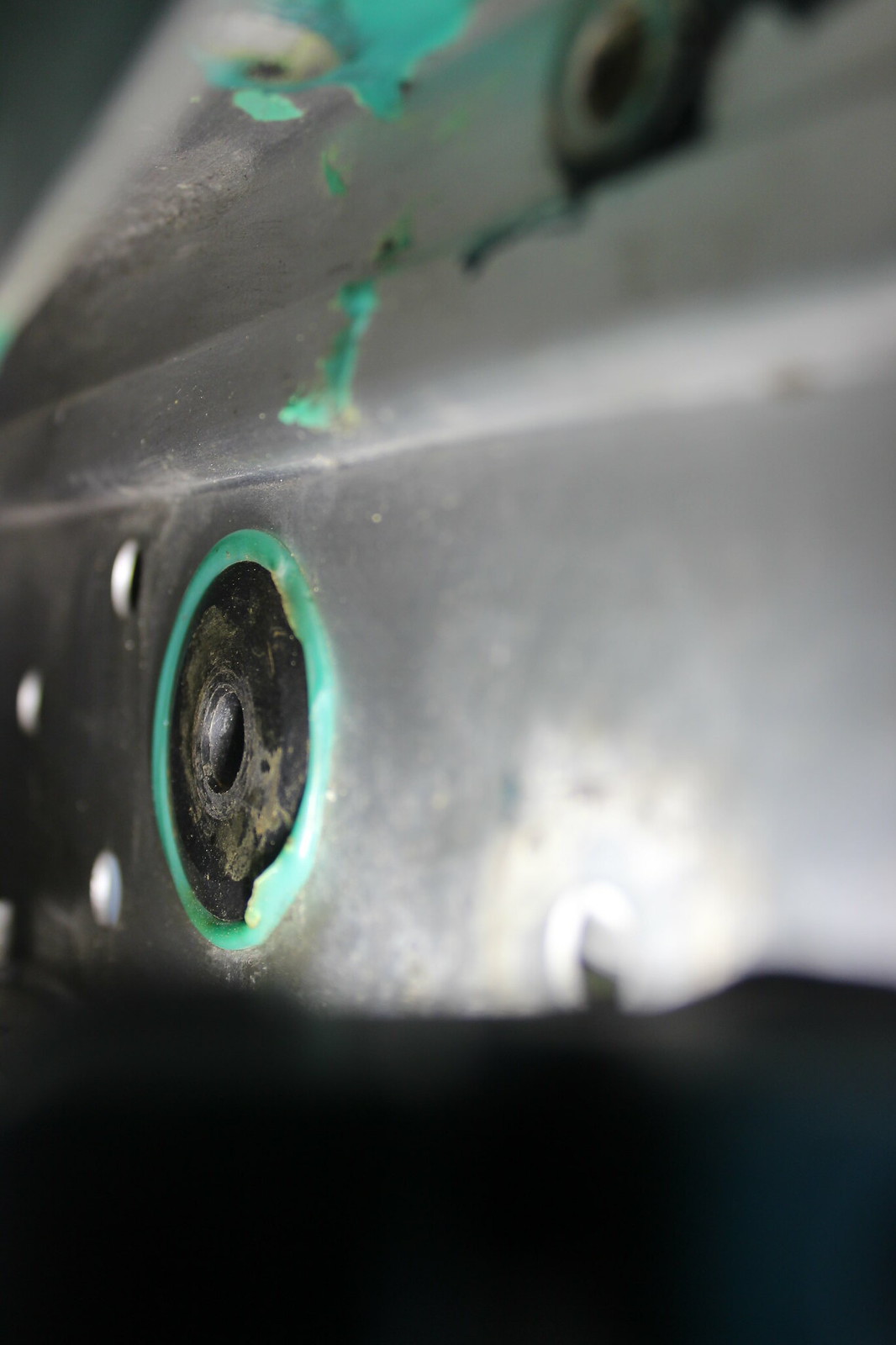

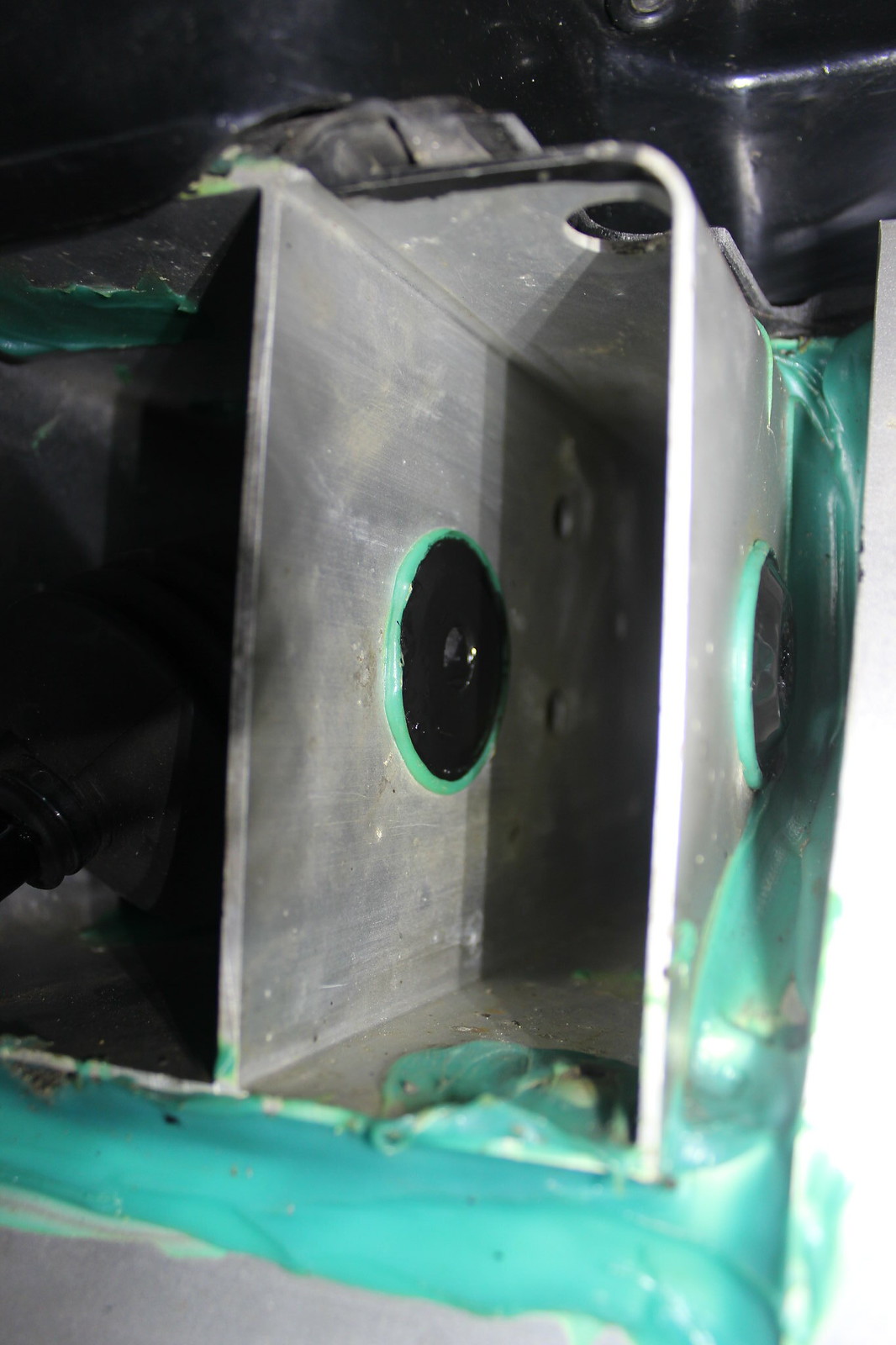

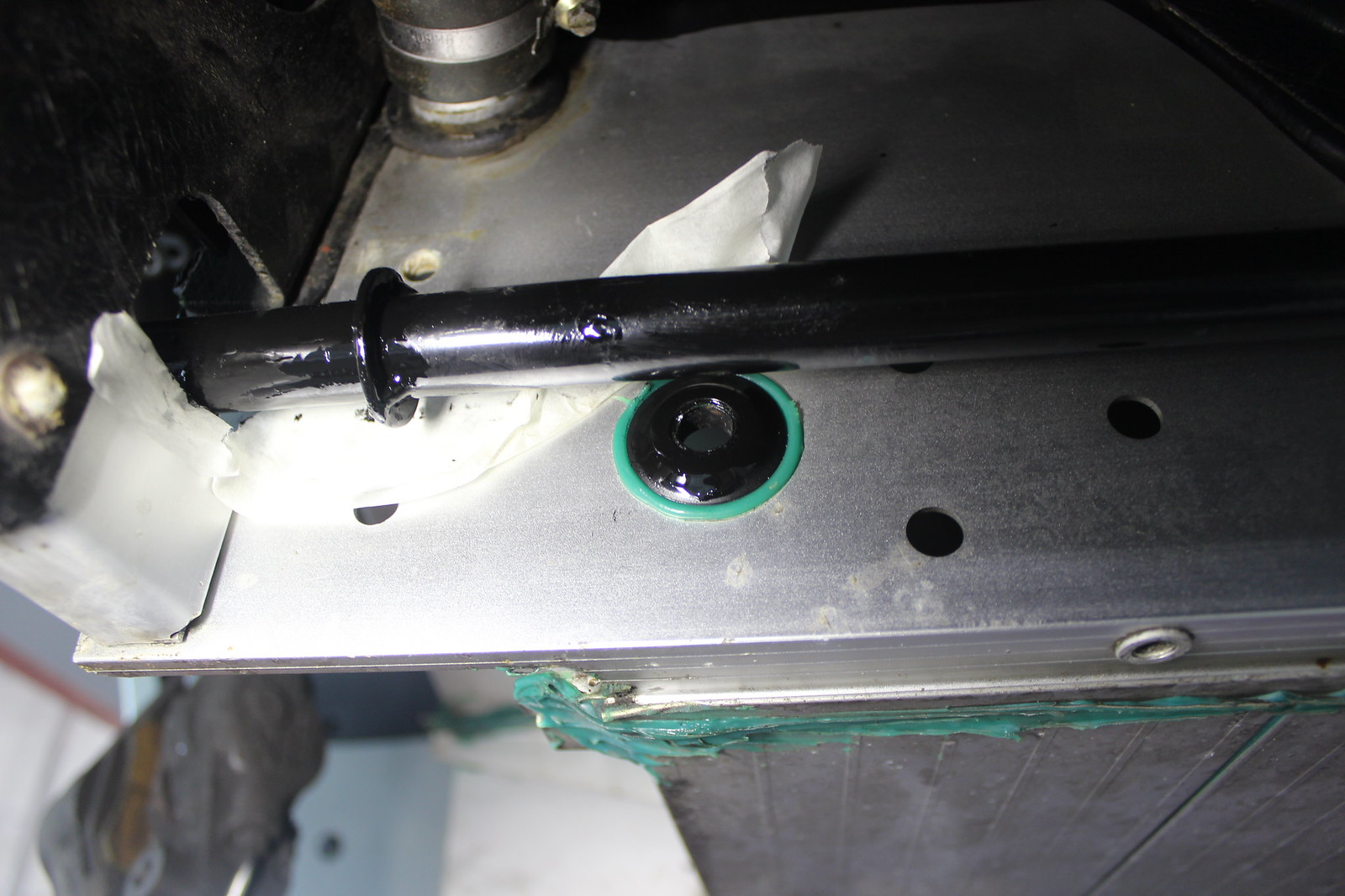

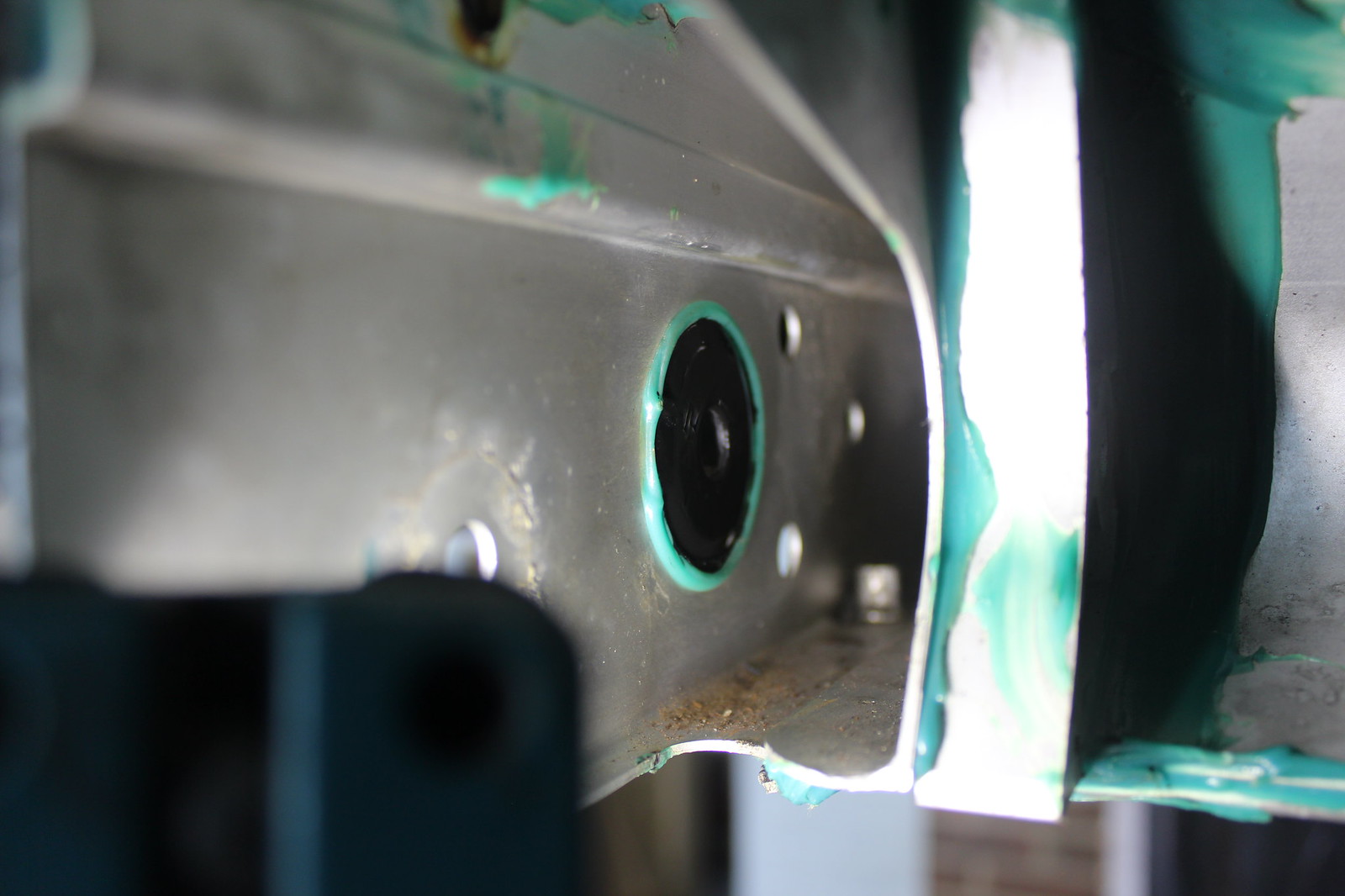

Before wire brushing one of the the steel inserts…

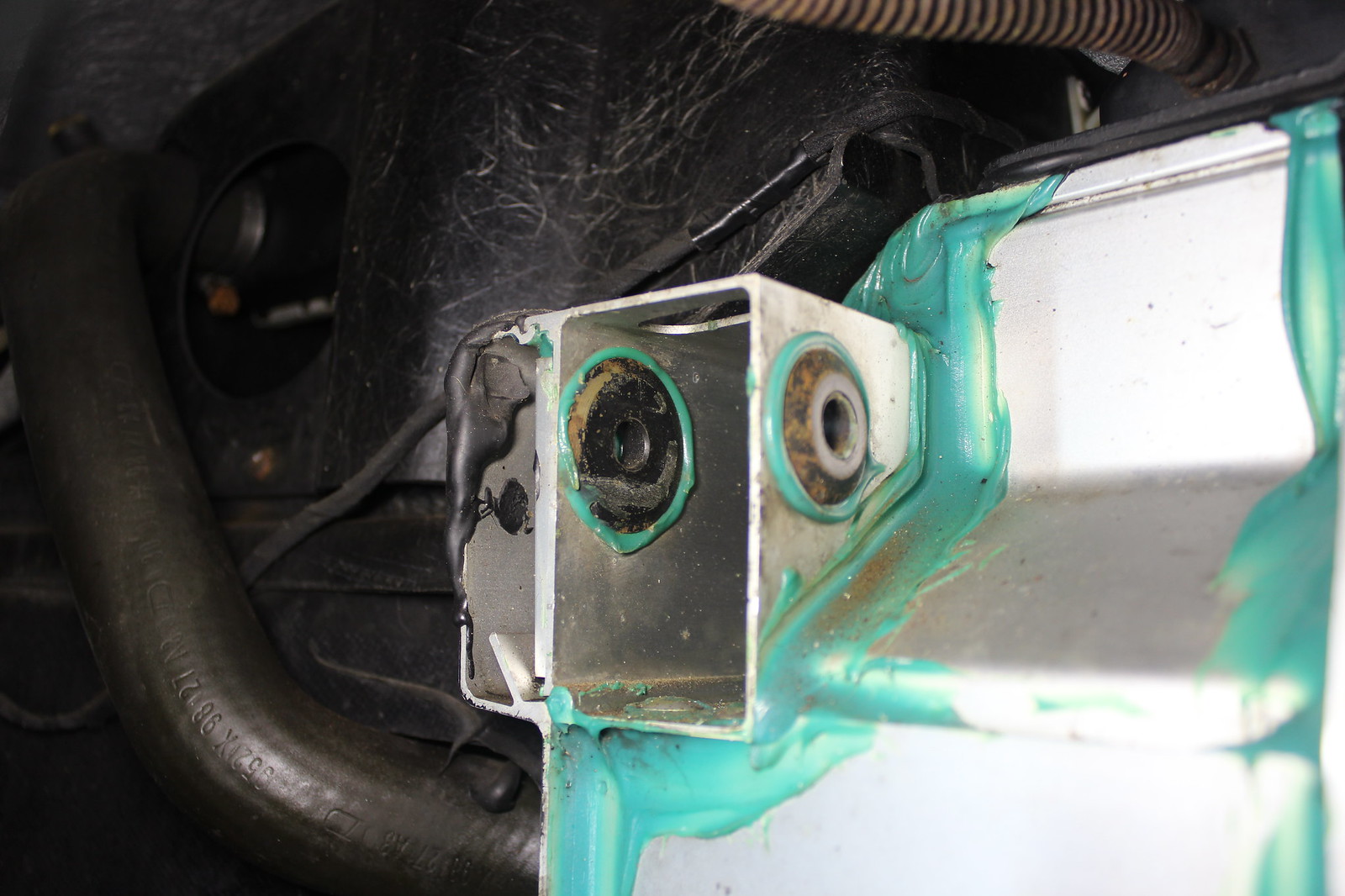

…and after. Clear to see the original coating of the steel insert has failed which would allow galvanic corrosion with the presence of an electrolyte/water.

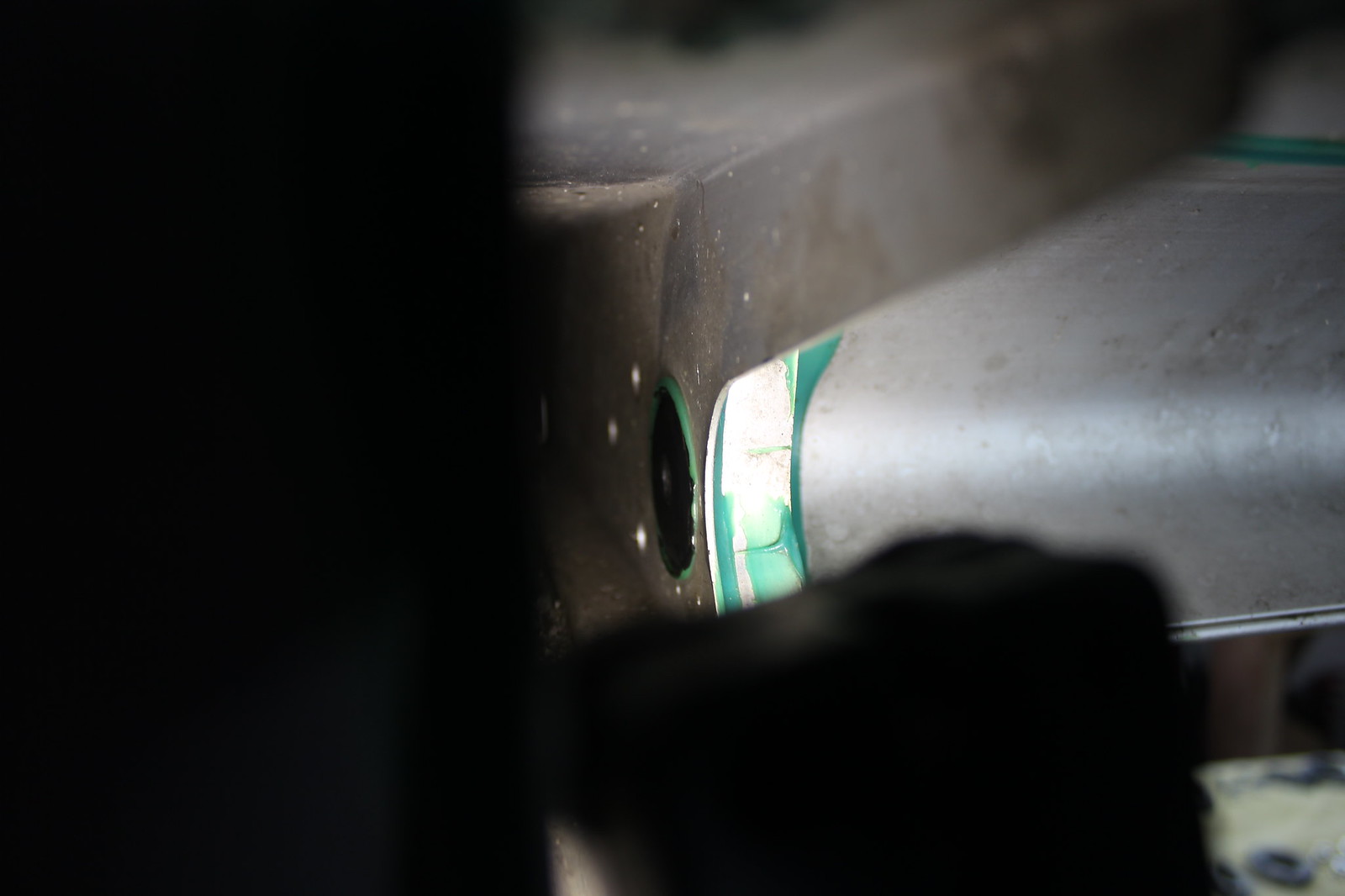

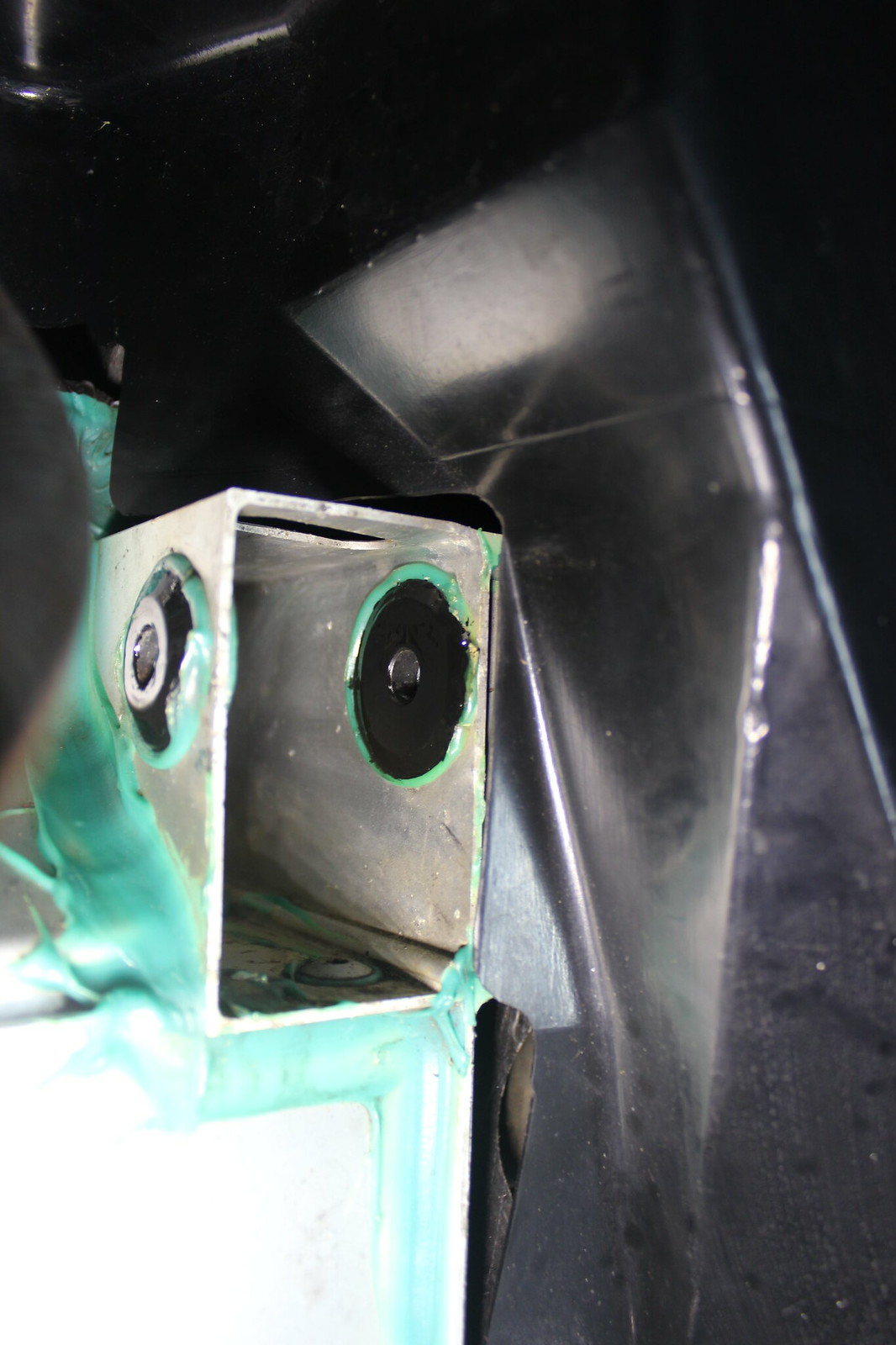

This is the worst I could find on my Elise. The very beginning of some corrosion to the outer edge of the chassis but nothing of any concern and very good for a 20 year old car really!

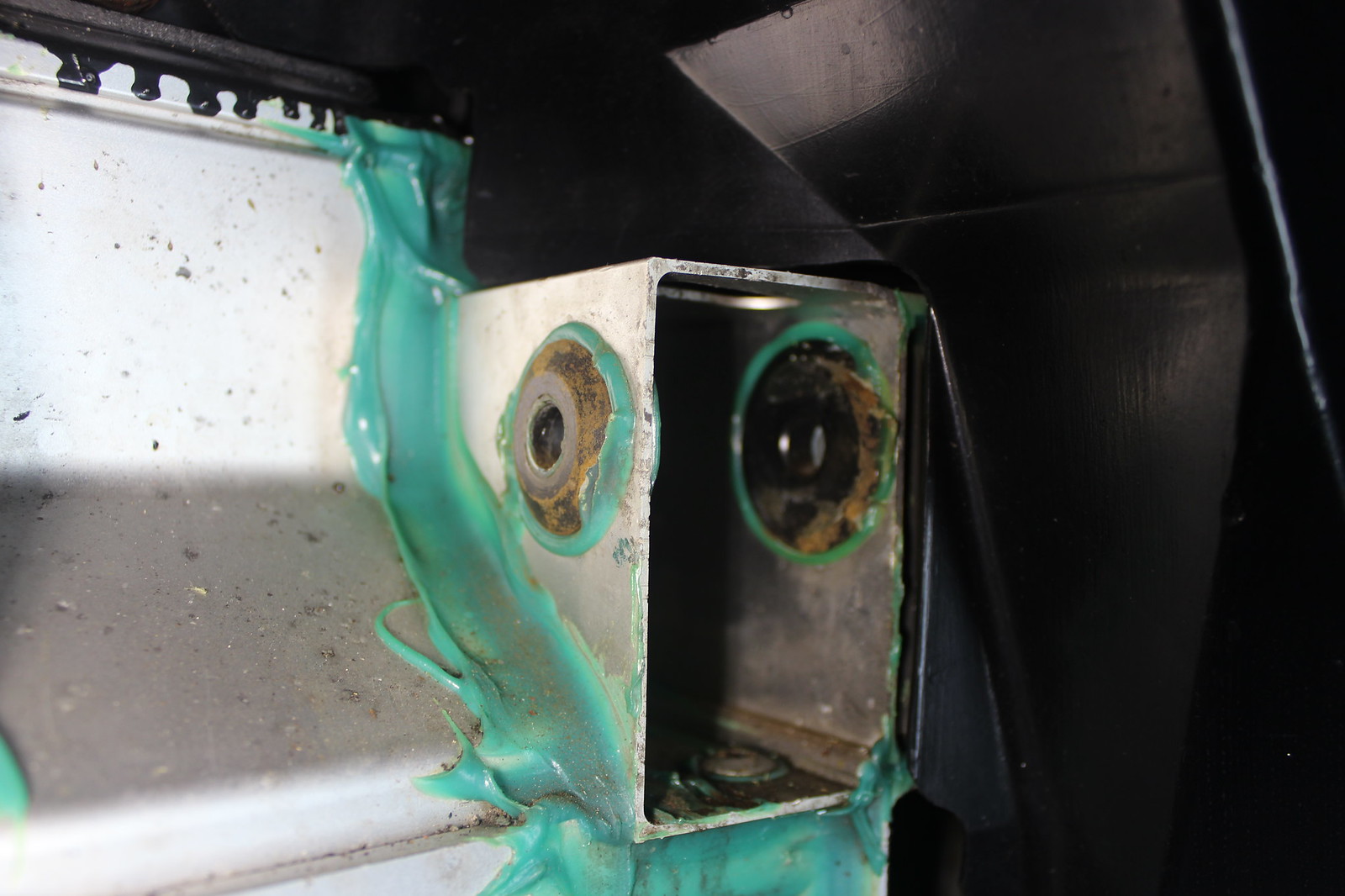

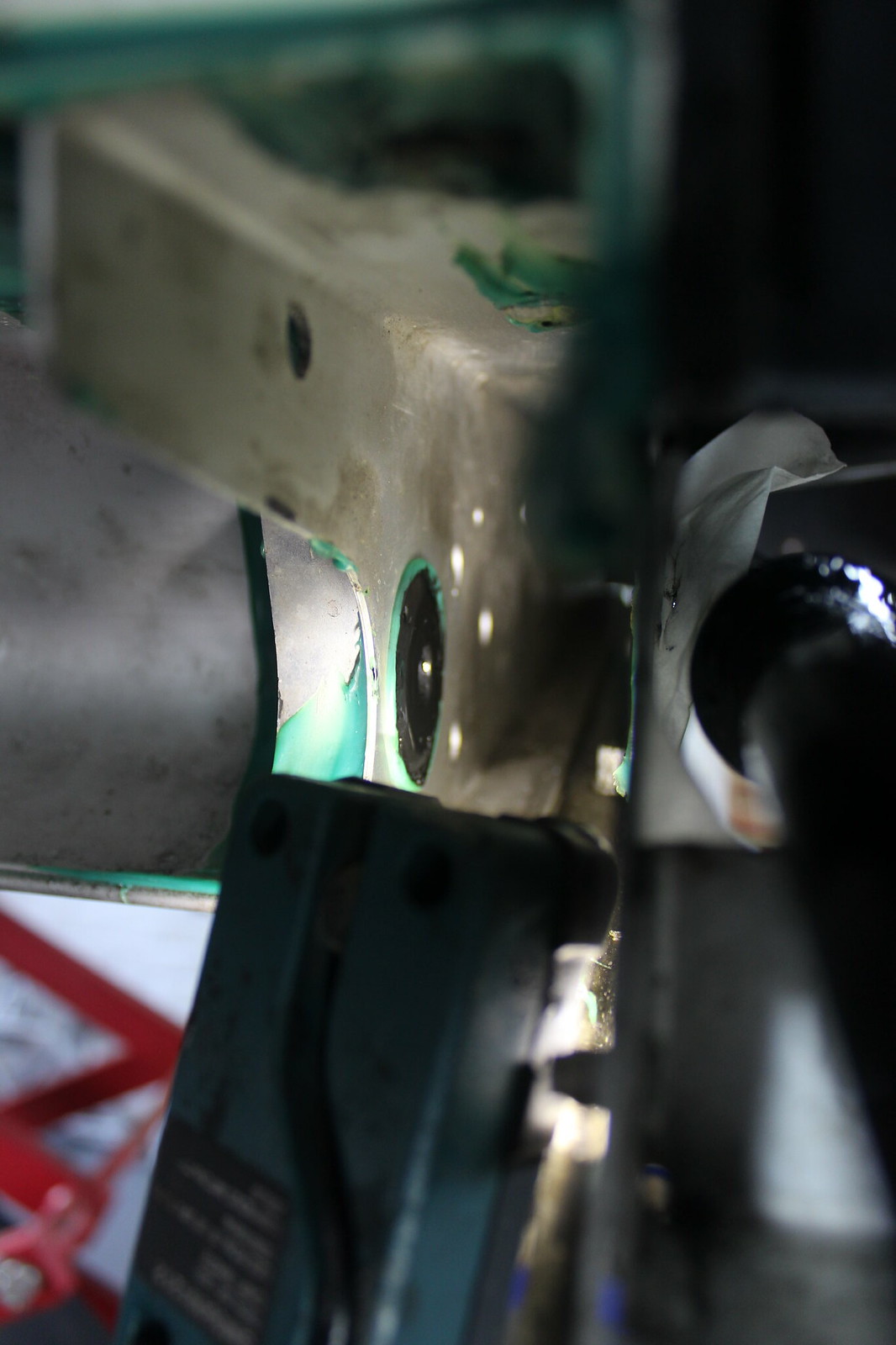

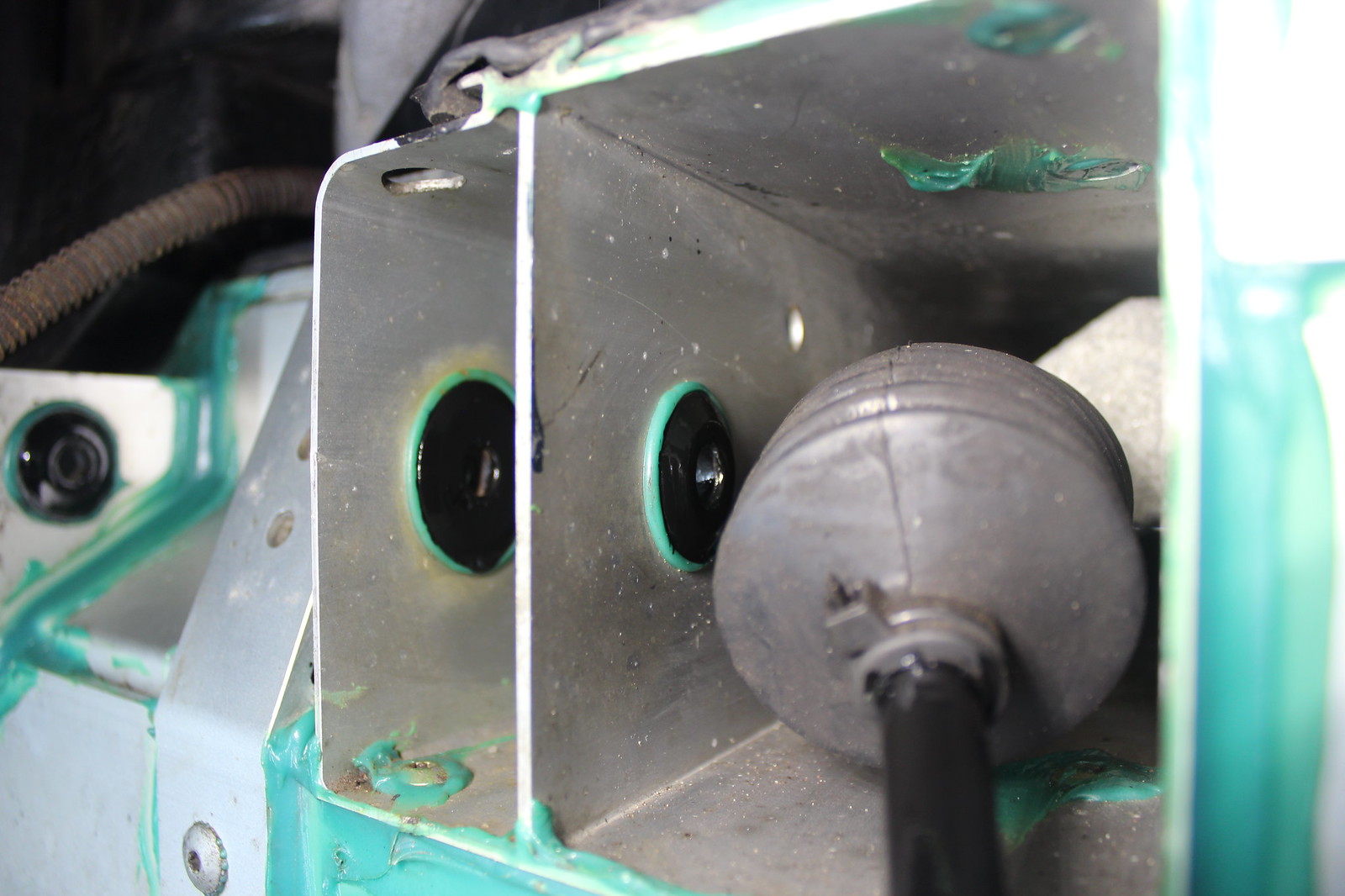

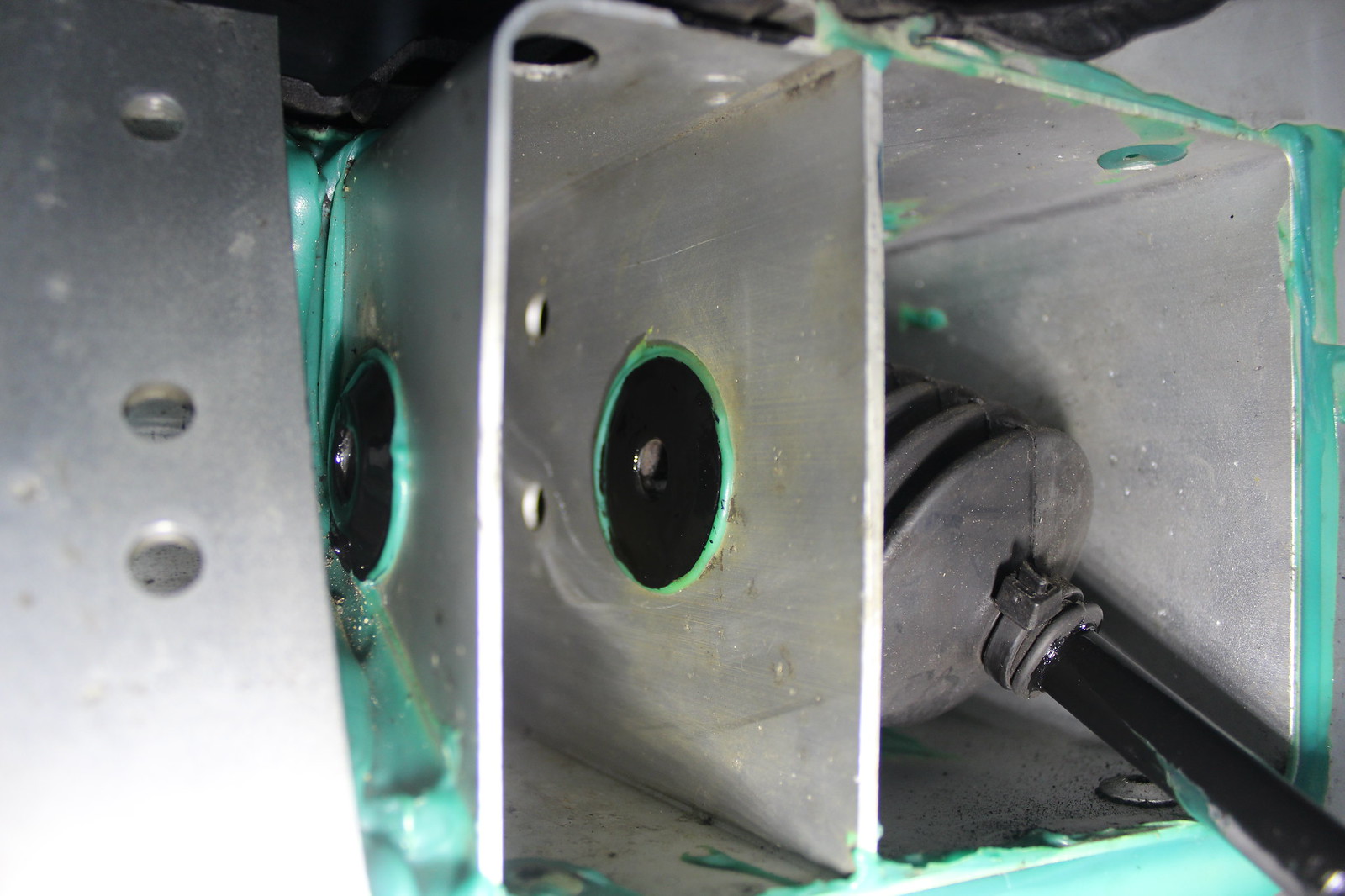

I didn’t want to leave the steel inserts in the same state before reassembly for a couple of reasons. Firstly they don’t look very nice in rusty brown but secondly and more importantly to prevent any of that galvanic corrosion I talked about in my previous post. A couple of layers of POR15 black paint would do nicely. Though to be honest, in my ownership at least, the Elise will only ever get wet when it is washed and that will only need to happen around 5 times a year. In winter it will be hibernated so the chance of any galvanic corrosion of the chassis will be very slim with no electrolyte!

I didn’t use the POR15 degreaser or metal prep here as if they get onto the aluminium they could both potentially make things worse by damaging the anodising or getting into any existing corrosion. I just wire brushed the steel inserts then went over them with a toothbrush to remove any dust.

Again these are just some of the pictures I took. There are more as a record of condition but I won’t put them all here.

I gave each insert a couple of thin coats which was allowed at least a week to cure before I got round to reassembling everything. They also got a layer of corrosion block grease during fitting the wishbones and a coat ACF-50 before and after fitting the wishbones. So any areas that might have been missed with paint or any existing corrosion got sealed.