As I said in my previous post I decided on using POR15 on the wishbones and other steel parts. The main reason I chose it was that I could do it all myself. I am also not a fan of powder coating which is one of the other common options. In my experience with powder coated parts the coating always seems to lift off the metal letting moisture in then the steel just rusts underneath the coating going unnoticed until the coating all flakes off at some point. I read a fair bit about the POR15 coatings and plenty of good reviews too so it seemed like the right thing for this job.

This is what the makers have to say about why their Cleaner Degreaser should be used:

POR-15® Cleaner Degreaser removes grease, oil, mildew, algae, musty odors, soap films, wax. Use it to clean canvas, vinyl, nylon, holding tanks, grease traps, auto parts and more. Adhesion is important with most paints but has to be perfect for POR-15 to achieve its maximum effectiveness. A solvent wipe before painting didn’t work with POR-15; in the lab we found it did more harm than good by leaving a residue that didn’t help with adhesion or appearance. We had to come up with a substance that would clean metal without leaving a residue. What we developed, POR-15® Cleaner Degreaser, contradicts all accepted theories about metal prep products: its water-based, not solvent-based and it cleans without leaving residues. In laboratory adhesion tests, our POR-15® Rust Preventive coating using POR-15® Cleaner Degreaser first to clean the bare metal far exceeded every other prep product we found in the marketplace.

Obviously you have to read all this kind of thing with a certain amount of scepticism as they would prefer people to buy their degreaser over anyone else’s, even if others work just as well! But in the grand scheme of things the POR15 Cleaner Degreaser isn’t too expensive, I know it will not have any adverse effects on the effectiveness of the following stages and you can never have too much degreaser, any spare will get used.

Having already wire brushed the wishbones I could start with this first stage of the POR15 treatment.

A bowl of warm water and some warm water in a spray bottle to dilute some of the POR15 Cleaner Degreaser into.

An old toothbrush is perfect for this.

I changed the warm water for rinsing a few times throughout.

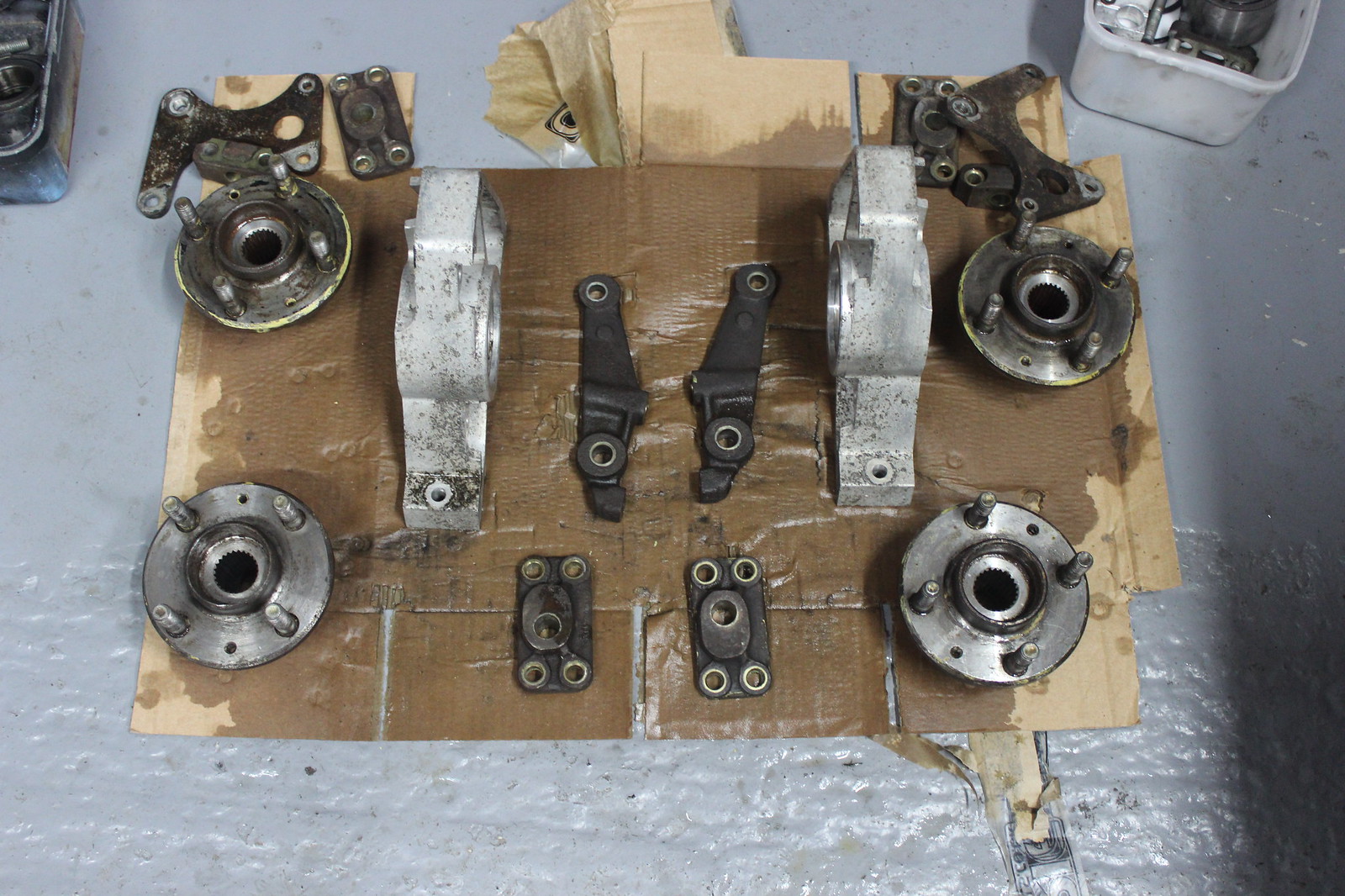

There were also a number of other parts like the hub carriers, steering arms etc that needed a good clean so I just did everything at once.

Hub carriers underway. There was some pretty well stuck on Duralac in places. I found a chisel was the best thing for scraping in off.

One of the disc guards.

A steering arm.

Some parts went through the process a couple of times being left covered in degreaser for a while to allow it to soak between rinses.

Eventually things were pretty clean.

Once everything had dried out I went over the steel parts with a wire brush to make double sure any loose rust was gone.

One of the rear brake caliper brackets.

An upper rear ball joint plinth.

A lower ball joint plinth.

Steering arm.

Drive flange.

After this everything got another quick rinse with some degreaser and warm water and left to dry.

Wasn’t quite sure what to do with the disc guards so last minute decided to prep them for painting too as the surface pitting on them was beyond polishing out.

The rear uprights looking so much better after a good clean. I had a go at wire brushing the one on the right to remove the last of the dirt. I wasn’t quite sure what the best thing to do with them all was but after how long this took I was pretty sure wire brushing was not the answer!