There was a bit of play in the gear change. To be honest it wasn’t too bad but I really hate feeling any slack in a cars controls so I took a look at the linkage to see if I could find anywhere with any slack and if I could do anything to tighten up the whole gear shift feel.

This image shows the design of the shift linkage used on 6 speed manual transmissions used in STI Subaru models. This isn’t specifically a Forester STI linkage but the FSTI one looks like this.

There are 3 joints in the linkage that could wear and cause slack in the gear change. There also doesn’t need to be much movement in one or all of the joints to result in quite a lot of slack in the linkage at the gear knob.

I started my search for wear or slack at the 2 joints under the car as they are the ones exposed to the elements and therefore most likely to wear. The one closest to the gear knob is effectively inside the car so less likely to be the cause of the problem.

I wasn’t quite sure how the joint was going to come out but I just started undoing things until it came out.

This bracket for the lower part of the linkage had to come off to make room for access.

Now I could get at the bolts on the joints though the top of the bolt that can’t be seen in this picture doesn’t have an ordinary hex head.

It has a round head with two flats on it. I was able to see this with a mirror.

The round head with two flats can bee seen here.

If I remember right, the horizontal bolt didn’t have clearance to come out so I had to tap out the roll pin that holds the linkage to the gearbox shaft. I found a decent length bit of steel the same diameter as the roll pin…

…put it into position and tapped out the roll pin.

Eventually the joint came free.

Here you can just see the shiny gearbox selector shaft that the linkage was removed from.

The joints removed.

The joints disassembled.

It was pretty obvious that there was some slack in both joints. The inner metal collar could move around within the bush around it and would just drop through it with no resistance. Click the image below to see a video of this.

It looks like the nylon bushes were produced with ridges on their inner surface, maybe to hold grease, which have worn down and worn marks into the metal collar.

Ideally I would just replace the bushes, assuming they were the only worn part. After a bit of searching the internet though and finding a thread on subaruforester.org it was clear that finding some replacement bushes wasn’t going to be simple. There seem to be some variations with year of manufacture as well as the variations with the Forester STI compared to Impreza models. So while there were some replacement bushes available for Impreza models nobody at the time could be certain which ones would fit any particular FSTI of a particular age.

The additional problem was that the inner metal collars could also have worn such that new bushes might not remove all the slack. So with this problem and the potential difficulty in finding new bushes I decided to take a different approach and simply turn some new inner collars with a very slightly larger outer diameter than the ones I removed. This would account for any wear in either or both the bushes and collars. This was also the quickest and simplest way to fix the problem for me.

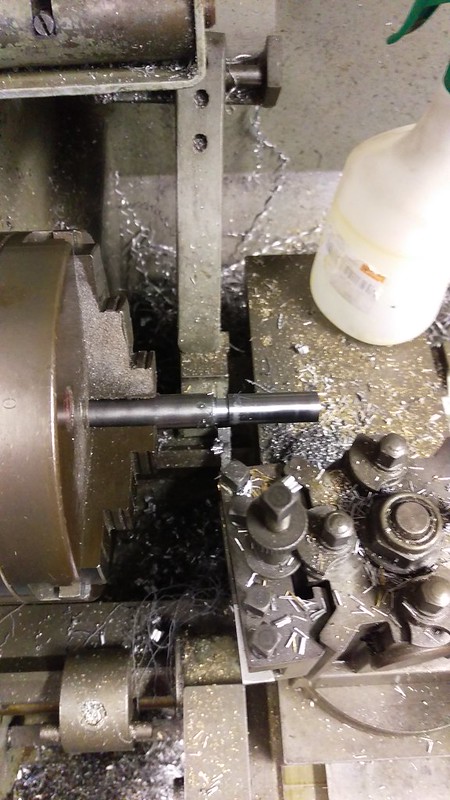

I got hold of some mild steel and machined some new collars.

Test fit before parting off.

Old and new collars.

Everything ready for reassembly with the new collars and some fresh grease.

All assembled. Now with no slack in the joints at all.

Back on the car.

All sorted then right? Well not quite. This made a big improvement but the third joint had obviously worn too as there was still a little play in the linkage. So I did the same for that.

Old collar removed.

New one fitted.

No more sloppy gear change! There is now zero slack and it feels so much better to use.

To make the feel of the gear change even more positive I also replaced the large rubber bushes at the gearbox end of the fixed rod with some poly equivalents.

The poly bushes I fitted are by Hardrace, part number 7123. Link to the Hardrace site. I bought them from H-Tune via eBay.